Augmented Reality (AR) has already revolutionized industries such as gaming and entertainment, but its potential impact on manufacturing and design is equally significant. With the ability to overlay digital information onto the physical world, AR has the power to transform how products are designed, manufactured, and assembled. From streamlining the design process to improving safety on the factory floor, the possibilities are endless.

What Is Augmented Reality (AR)?

Augmented Reality (AR) is a technology that enhances a user’s perception of the physical world by overlaying digital content onto it. The aim of AR is to create an interactive and immersive experience for the user by superimposing computer-generated images, videos, or sounds onto the real-world environment.

AR technology works by utilizing a combination of sensors, cameras, and computer algorithms to capture and process data from the surrounding environment. This data is then used to create a virtual layer that is overlaid on top of the real-world view. AR can be experienced through a variety of devices such as smartphones, tablets, and AR glasses, and it can be applied to various industries, from healthcare and education to entertainment and retail.

There are two main types of AR: marker-based and markerless AR. Marker-based AR uses a visual marker, such as a QR code or image, to trigger the display of virtual content. The camera detects the marker and overlays the virtual content on top of it. On the other hand, markerless AR does not require a visual marker and instead uses computer vision algorithms to detect and track the physical environment in real-time.

Current Use of AR in Manufacturing and Design

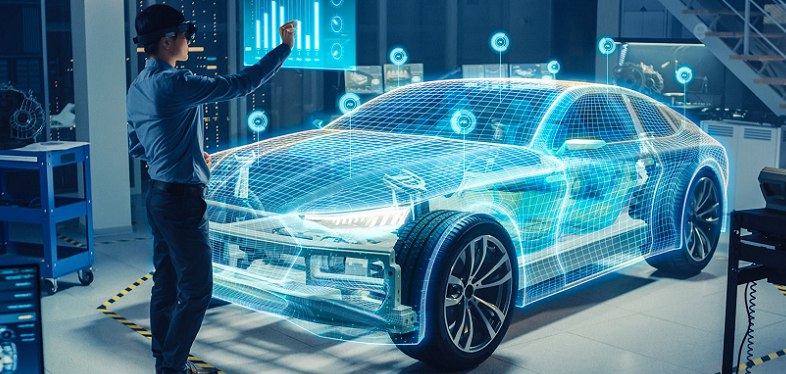

Augmented Reality (AR) has already found applications in various ways in the manufacturing and design industry. One of the most significant benefits of AR in manufacturing and design is its ability to create an interactive and immersive experience for the user. AR can enhance the user’s perception of the physical world by overlaying digital content onto it.

AR technology can be used for various purposes in the manufacturing and design industry. AR can be used to visualize and explore 3D designs in a real-world context. It can also be used to create virtual prototypes and test them in a real-world context. AR can be utilized to guide workers through complex assembly processes, reducing errors and improving efficiency. AR can be used for maintenance and repair tasks, providing workers with real-time access to critical information and instructions.

Moreover, AR technology can be used for training and education purposes, providing workers with interactive and immersive learning experiences. AR can be utilized to simulate dangerous or hazardous situations, allowing workers to practice safety procedures in a controlled environment. AR can also be used for sales and marketing purposes, allowing customers to interact with products in a virtual environment.

Some companies have already started utilizing AR in their manufacturing and design processes. Boeing, for instance, uses AR to guide workers through complex assembly processes, reducing errors and improving efficiency. Ford uses AR to visualize designs and create virtual prototypes, allowing designers to identify design flaws and make necessary modifications.

Siemens uses AR for maintenance and repair tasks, providing workers with real-time access to critical information and instructions. Ikea uses AR for sales and marketing purposes, allowing customers to visualize and interact with furniture in a virtual environment. Dassault Systèmes uses AR for design visualization and prototyping, allowing designers to see how the product will look and function in its intended environment.

Advancements in AR Technology

In recent years, there have been significant advancements in Augmented Reality (AR) technology. These advancements have improved the performance, usability, and accessibility of AR. One of the most significant advancements in AR technology is the development of markerless AR. This technology does not require a visual marker and instead uses computer vision algorithms to detect and track the physical environment in real-time.

Another significant advancement in AR technology is the development of AR glasses. AR glasses provide a more immersive and hands-free experience for the user, allowing them to access information without having to hold a device. AR glasses also have the potential to be used in various industries, such as healthcare and education.

AR technology has also become more accessible, with the integration of AR features in smartphones and tablets. This has made AR more accessible to a wider audience and has opened up new opportunities for businesses to integrate AR into their products and services.

The development of AR cloud technology is another significant advancement in AR technology. AR cloud technology allows AR content to be stored and accessed in the cloud, providing a more seamless and immersive AR experience. This technology also enables shared AR experiences, allowing multiple users to interact with the same AR content in real-time.

The development of AR software tools has made it easier for businesses to create and deploy AR content. AR software tools provide businesses with the ability to create AR content without requiring advanced technical knowledge.

Companies Currently Using AR in Manufacturing and Design

Many companies have already incorporated AR technology into their manufacturing and design processes. Several of the more well known examples are listed here.

- Boeing: Boeing uses AR to guide workers through complex assembly processes, reducing errors and improving efficiency.

- Ford: Ford uses AR to visualize designs and create virtual prototypes, allowing designers to identify design flaws and make necessary modifications.

- Siemens: Siemens uses AR for maintenance and repair tasks, providing workers with real-time access to critical information and instructions.

- Ikea: Ikea uses AR for sales and marketing purposes, allowing customers to visualize and interact with furniture in a virtual environment.

- Dassault Systèmes: Dassault Systèmes uses AR for design visualization and prototyping, allowing designers to see how the product will look and function in its intended environment.

- Caterpillar: Caterpillar uses AR for operator training, allowing workers to practice equipment operations in a controlled environment.

- Bosch: Bosch uses AR for assembly and maintenance tasks, providing workers with real-time guidance and information.

- NASA: NASA uses AR for astronaut training, providing immersive and interactive simulations of space missions.

- General Electric: General Electric uses AR for quality control and inspection, providing workers with real-time feedback on product quality.

- Volkswagen: Volkswagen uses AR for design visualization and virtual prototyping, allowing designers to see how the product will look and function in a real-world context.

Future Applications of AR in Manufacturing and Design

The future of Augmented Reality (AR) in manufacturing and design is promising, with potential applications in various areas. One potential application of AR is in the creation of digital twins. Digital twins are virtual representations of physical products and processes, and AR can be used to visualize and interact with digital twins in a real-world context.

Another potential application of AR in manufacturing and design is in the area of remote collaboration. AR can be used to enable remote teams to collaborate on designs and projects in real-time, providing a more efficient and effective collaboration experience.

AR can also be used for real-time quality control and inspection. AR can provide workers with real-time feedback on product quality, helping to identify defects and reduce waste.

In the area of training and education, AR can be used to provide workers with immersive and interactive learning experiences. AR can be used to simulate dangerous or hazardous situations, allowing workers to practice safety procedures in a controlled environment.

AR can also be used for product customization and personalization. AR can provide customers with an interactive and immersive experience, allowing them to visualize and customize products in a real-world context.

AR can be used for predictive maintenance and predictive analytics. AR can provide workers with real-time data and insights, helping to identify potential maintenance issues before they become major problems.

Challenges and Limitations of AR in Manufacturing and Design

While Augmented Reality (AR) has numerous benefits and potential applications in manufacturing and design, there are also some challenges and limitations associated with this technology.

One of the main challenges of AR is the accuracy of the tracking and mapping of physical objects. AR relies on accurate tracking of the physical environment to overlay digital content onto it, and any inaccuracies can cause the AR experience to be disjointed and difficult to use.

Another challenge is the availability of hardware and software. While AR technology is becoming more accessible, it still requires specialized hardware and software to create and deploy AR content. This can be a barrier for small businesses or those without access to the necessary hardware and software.

AR also requires a significant amount of data processing and storage, which can be challenging for businesses without access to powerful computing resources. This can limit the scalability of AR solutions and make them less practical for large-scale deployment.

Another limitation of AR is the need for specialized training and education for workers to use it effectively. AR is a new and complex technology, and workers may require specialized training to use it effectively. This can be a time-consuming and expensive process for businesses.

There are limitations to the types of physical environments and objects that AR can effectively track and map. Certain types of environments or objects may be more difficult to track accurately, which can limit the effectiveness of AR in these contexts.