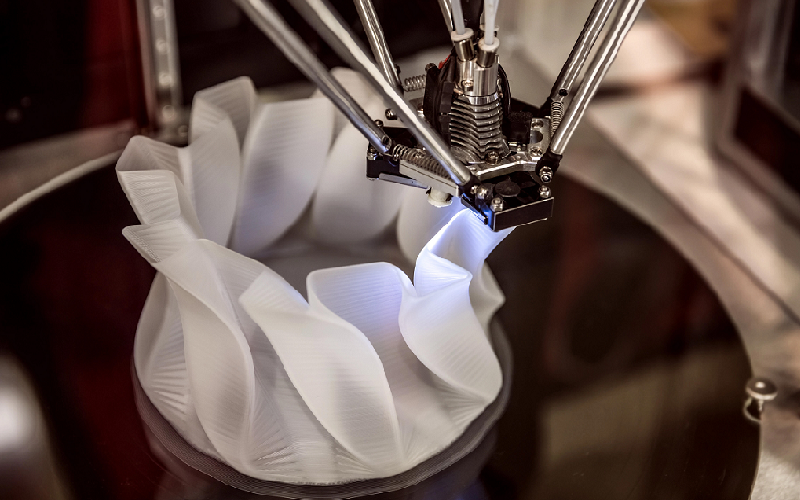

In a world where the marvels of 3D printing have already reshaped manufacturing, design, and countless other industries, a new frontier is emerging that promises to redefine our understanding of fabrication and material science: 4D printing. This revolutionary technology extends beyond the spatial dimensions of 3D printing, introducing an exciting fourth dimension – time. Unlike traditional 3D printing, 4D printing allows objects to transform and adapt over time in response to external stimuli, such as heat, light, or water.

Historical Context and Evolution of 4D Printing

Before getting into the intricate world of 4D printing, it’s essential to understand its roots and how it evolved from its predecessor, 3D printing. This journey not only highlights technological progress but also sets the stage for appreciating the innovative leap that 4D printing represents.

Brief History of 3D Printing

3D printing, the precursor to 4D printing, revolutionized manufacturing with its debut in the 1980s. Initially known as rapid prototyping, it allowed designers to quickly create physical models from digital designs. This technology evolved from using basic polymers to a wide range of materials, including metals and bio-materials. Over the years, 3D printing transformed from a tool for rapid prototyping to a full-fledged manufacturing solution, used in industries ranging from aerospace to healthcare.

The Development of 4D Printing Technology

The concept of 4D printing emerged as researchers began exploring ways to make 3D-printed materials react to external stimuli. This idea was first introduced around the early 2010s by a team of scientists, including Skylar Tibbits, at the Massachusetts Institute of Technology (MIT). They envisioned materials that could self-assemble or change shape in response to environmental changes, thus adding the dimension of time to the 3D printing process. This development marked a significant shift from static to dynamic and responsive materials.

Key Innovators and Institutions in 4D Printing

MIT’s Self-Assembly Lab, led by Tibbits, has been at the forefront of 4D printing research. Collaborations with organizations like Stratasys, a leader in 3D printing technology, and Autodesk, a software company specializing in 3D design, further propelled the development of 4D printing. Other institutions worldwide, including the University of Colorado Boulder and Singapore University of Technology and Design, have also made substantial contributions, pushing the boundaries of what’s possible with 4D printing [1].

Understanding 4D Printing

To fully grasp the revolutionary nature of 4D printing, it is imperative to delve into its defining characteristics, how it diverges from 3D printing, and the underlying technologies that enable its unique capabilities. This understanding lays the foundation for appreciating the innovative applications and future potential of 4D printing.

Definition of 4D Printing

4D printing, at its core, is an extension of 3D printing technology with one crucial addition – the dimension of time. This process involves creating objects that can transform or self-assemble over time when exposed to environmental stimuli such as temperature, light, moisture, or magnetic fields. The ‘4D’ aspect refers to these dynamic changes occurring post-production, enabling printed objects to adapt, repair, or reconfigure themselves autonomously.

Comparison Between 3D and 4D Printing

While 3D printing creates static objects, 4D printing takes this a step further by embedding the potential for motion and transformation within the printed objects. The key difference lies in the materials used and the design process. In 4D printing, materials are not just selected for their structural properties but also for their ability to respond to specific triggers. The design process, consequently, involves not just the physical dimensions but also planning for the object’s temporal behavior [2].

Core Technologies Behind 4D Printing

The technological advancement of 4D printing is anchored in two main areas: smart materials and sophisticated design algorithms. Smart materials, such as shape-memory polymers and bio-compatible materials, are central to 4D printing. These materials can be programmed to respond predictably to external stimuli. Design algorithms are equally crucial, as they allow for precise control over how and when the object will change shape or properties. Advanced computational modeling and simulation play a significant role in predicting the behavior of these materials over time.

Materials Used in 4D Printing

A diverse range of materials is being explored for use in 4D printing. Shape-memory alloys and polymers, hydrogels, and temperature-responsive fibers are among the most commonly used. Researchers are also investigating the use of bio-based materials and composites that offer environmental benefits. The choice of material depends largely on the intended application and the specific environmental trigger it is designed to respond to.

Applications of 4D Printing

The transformative potential of 4D printing spans across various industries, offering innovative solutions and opening new possibilities. From healthcare to environmental sustainability, the applications of 4D printing are as diverse as they are impactful.

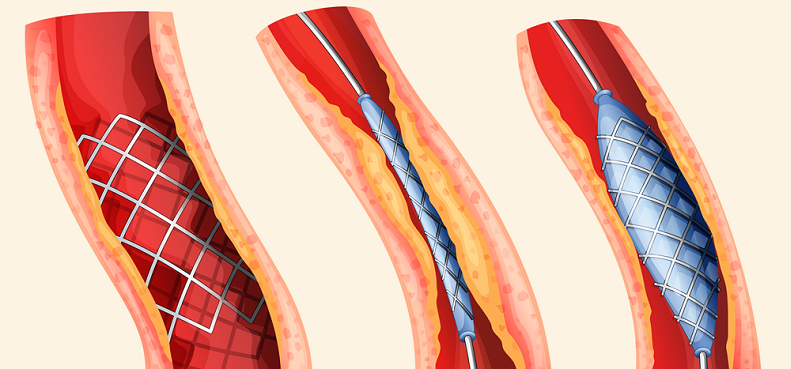

Medical Field Innovations Involving 4D Printing

In the medical sector, 4D printing is paving the way for groundbreaking advancements. One notable application is in the development of biomedical devices that can change shape inside the body, adapting to new anatomical realities post-surgery. This includes stents that can expand or contract as needed and drug delivery systems that release medication in response to specific physiological conditions. Additionally, researchers are exploring the potential for 4D bioprinting, where living cells are incorporated into the print material, leading to tissue and organ fabrication that adapts and evolves over time [3].

Aerospace and Automotive Industries Using 4D Printing

The aerospace and automotive industries are harnessing 4D printing to create components that can adapt to changing environmental conditions. For instance, in aerospace, 4D printed materials are being developed for wings or air intake structures that change shape to optimize aerodynamics in response to flight conditions. In the automotive sector, manufacturers are exploring 4D printed materials for parts that can adapt for efficiency, such as air vents that automatically open or close based on temperature or vehicle speed.

Construction and Architecture With 4D Printing

In construction and architecture, 4D printing is introducing new paradigms in building design and material use. This includes the development of self-assembling structures that can transform from a compact form to a predetermined final shape, potentially reducing transportation and assembly costs. Adaptive building materials that react to environmental factors, like temperature-responsive tiles that adjust insulation properties, are also a focus, offering new ways to create energy-efficient buildings.

Consumer Products and Fashion Using 4D Printing

The consumer goods and fashion industries are also benefiting from 4D printing. In fashion, designers are experimenting with fabrics and accessories that change shape or color in response to environmental stimuli, paving the way for customizable and adaptive clothing. In consumer products, 4D printing enables the creation of objects that can self-assemble or change shape for convenience, such as flat-packed furniture that assembles itself in response to heat or moisture.

Environmental and Sustainable Solutions Involving 4D Printing

4D printing also holds promise in environmental sustainability. One area of focus is the development of materials and structures that can adapt to changing environmental conditions, reducing waste and improving efficiency. This includes water filtration systems that expand or contract in response to pollution levels and responsive agricultural systems that adjust to weather changes for optimal crop growth.

Future Prospects and Trends of 4D Printing

The possibilities of 4D printing are vast, ranging from everyday conveniences to large-scale industrial applications. Understanding these prospects and trends helps in visualizing the future landscape shaped by 4D printing.

Predictions for Future Developments in 4D Printing

The future of 4D printing is likely to witness significant advancements in materials science and computational modeling. We can expect the development of more sophisticated and responsive materials, capable of undergoing multiple transformations or being programmed for longer and more complex sequences of change. Additionally, the integration of artificial intelligence in design processes could lead to more intuitive and efficient creation of 4D printed objects, tailored to specific environmental or user-based triggers [4].

Potential Impact of 4D Printing on Various Industries

The impact of 4D printing is poised to be far-reaching. In the medical field, there could be a shift towards more personalized and adaptive medical devices and implants. The construction industry might see a revolution in building materials that adapt to environmental conditions, leading to more sustainable and resilient infrastructure. In manufacturing, the ability to create objects that can assemble themselves or change shape post-production could significantly reduce labor and transportation costs.

Research and Innovation Opportunities Involving 4D Printing

The realm of research and innovation in 4D printing is abundant with opportunities. One area ripe for exploration is the combination of 4D printing with other emerging technologies like nanotechnology or biotechnology. This could lead to the creation of even more complex and functional materials. Another promising area is the exploration of environmental applications, such as developing materials that can help in combating pollution or climate change.

The Role of 4D Printing in Shaping the Future

4D printing is set to play a crucial role in shaping our future, particularly in how we approach problems of sustainability, efficiency, and personalization. As this technology matures, it could lead to a paradigm shift in product design and material usage, where objects are no longer static but are dynamic and responsive entities. This shift has the potential to fundamentally change our interaction with the physical world, leading to more adaptive, efficient, and sustainable lifestyles and industrial practices.

References

[1] Beyond 3D Printing: Programming the Material World

[2] Micro/nanoscale 4D printing revolution: Manufacturing high-resolution transformable 3D structures

[3] Beyond 3D Printing – The Future is 4D

[4] From 3D to 4D printing: A review